Digital printers require more investment capital than traditional printers. When comparing the total purchase cost between conventional printing and digital printing (water, electricity, operator, service cost, ink, Fabric follow-up, etc.) , the cost of digital printing for one meter of fabric is about 1.5 times that of conventional printing.

The investment cost of a textile printing machine is determined by many factors.

The additional cost of digital printing is as follows:

In digital printing, there are two different printing technologies available: Scan Printing and single-pass printing.

Scanning printing refers to the nozzle movement around on the fabric (so called "scanning") .

For multi-pass scanning printing, only a few nozzles can be expected results. This reduces the cost of investment

in scanning printing machine.

Single-pass printing is a new printing technology, which can achieve faster printing speed with higher quality.

However, in order to achieve faster printing speed, it needs more nozzles. Thus, Single-pass printing is more expensive than scanning digital printing because more nozzles are needed to cover the entire width of the machine. Since the inkjet nozzle

is an expensive part, the more nozzles are included in the printing machine, the more expensive the machine is.

In addition, the additional cost of the electronic equipment that drives these machines has increased the cost of the machines

02.

Digital inkjet printing requires different types of ink. In digital inkjet printing, ink is sprayed onto the fabric through a number of tiny nozzles inside the head. This printing process requires the use of more liquid ink to prevent nozzle clogging and nozzle failure.

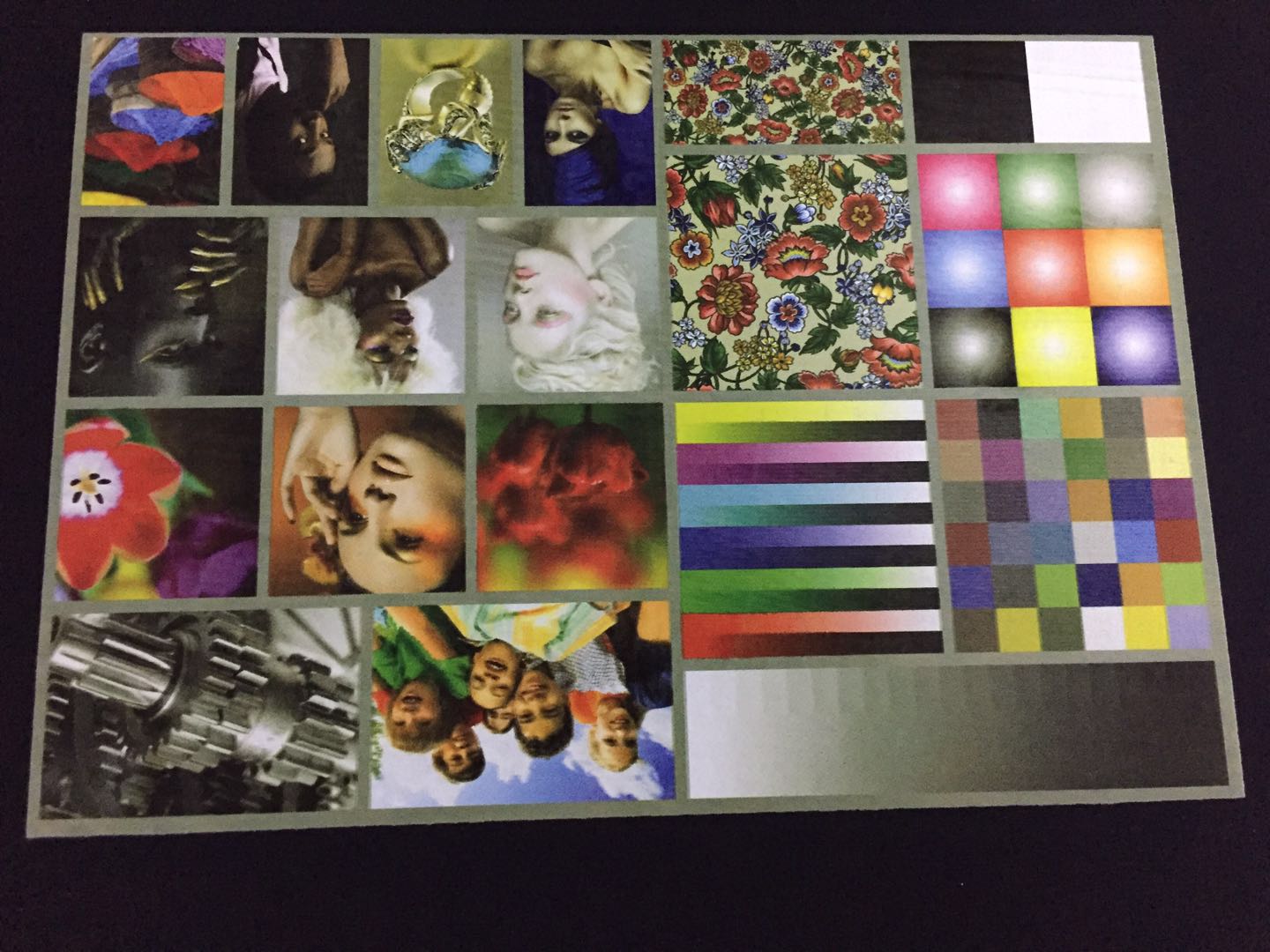

In addition, digital ink-jet printing can achieve high-quality printing, but only in the use of large-gamut ink to achieve.

The ink must also be very pure and free of impurities, to prevent erosion of the nozzle. Therefore, additional purification

steps are essential in production. Due to these special characteristics, digital printing ink is more expensive than traditional printing ink, thus increasing the cost of digital printing.

BENEFITS OF DIGITAL PRINTING

The additional investment in digital inkjet printing also provides a number of valuable advantages for textile printing machines, helping to save costs or create new revenue.

01

Reduce Labor Costs

The traditional printing machine must be handled by several operators because in the printing process there are many manual tasks must be performed by the operator. Therefore, traditional printing involves high labor costs. However, the digital inkjet printing machine is almost completely automated, which means that only one or two operators are needed to operate the machine.

If you run multiple machines, this number drops to the point where you need fewer than one operator per machine, because operators can run multiple machines simultaneously. Therefore, the transition to digital printing can help save labor costs of operating a printing machine.

02

NO SCREEN PRODUCTION COSTS

In digital printing, the pattern is printed directly on the fabric. Don‘t need a screen.

This not only saves precious screens make time but also saves the screen itself

and the additional costs of screen film, exposure, stretch costs.

03

REDUCE TURNAROUND TIME

With the help of digital printing, the factory can improve the printing machine productivity and shorten the turnaround time.

This enables the printing machine to ensure faster delivery and meet customer needs, while also taking on more printing work.

By applying digital printers to fast fashion brands, it has been shown that these brands are more willing to pay more for

one meter of fabric delivered in a few days than in a few weeks. Thus, the additional cost of digital inkjet printing can be

charged to the customers

04

FLEXABLE AND FAST DELIVER

Printing on the fabric that has been sold rather than sell the printed fabric

Due to the long turnaround time for traditional printing, fashion brands need to estimate the number of meters of printed fabric

they sell and use this as a basis for printing.

However, because digital inkjet printing speeds up the printing process, fashion brands can print in small batches and reorder when a certain type of clothing sells well. In an ideal world, with digital printing, there would be no such thing as a "discount sale" in the future, as fashion brands could quickly obtain the required number of printed fabrics.

05

THE AMOUNT OF INK IS REDUCED

Although digital printing ink is more expensive than conventional printing ink, the digital printing process helps

printing companies to reduce the amount of ink used.