The nozzle of the digital printer is a kind of consumption item. Daily maintenance should be very carefully, but even the most take care,

the nozzle will be broken someday always. At this moment, we should use one brand new printer nozzle to replace. How to test a printer

with a new nozzle after installation? What should we pay attention to?

01

Don’t use a syringe to test the nozzle to see if it is clogged before trying the nozzle, This is a very redundant and dangerous practice.

First of all, once the nozzle is filled with water, you turn on the machine with electricity before it is dry. lightly, the board burned; Heavily,

the complete printer will be burnt; Always the nozzle is filled with protective fluid, if you inject water into the head with a Syringe, which not only washes away the protective fluid from the head but also because the hand pressure is too large, it is easy to cause the NOZZLE air blockage,

resulting in ink output problem.

02

The surface of the printer nozzle is very fragile, absolutely, it can not bump and must be protected very well. Its surface

layer is one piece of aluminum flakes and the inside is coated with Crystal oscillator and very tiny ink tubes. Once touched,

it will be concave, deformation, and even broken, then the nozzle will be useless.

03

Also be careful when installing the printer nozzle, make sure the power is turned off and the nozzle is in place. After installation,

use hand to push the cart gently moving around, check whether its performance is smooth. do not connect the electricity before everything

confirmed ok. Because, if the printer does not in place, the cart is easy to break the printer head, but if felt by hand, put in and out is freely and controllable.

04

Do not carry any ink when connecting plug cables. Meanwhile, to ensure good contact with the socket, do not touch the pins, otherwise,

the nozzle will be burnt by short-circuiting.

05

Steel shaft should also be clean and smooth. Using paper towel carry some grease to clean. Do not put oil directly to the shaft, extra oil stains

will flow to the nozzle and causing damage.

06

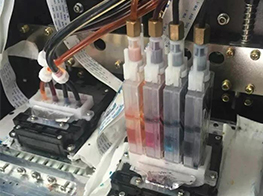

After mechanical and electric circuit confirmed OK, it is necessary to check the ink loading parts. First of all, look at the ink cartridges enough with ink or not. Second, check the small clean scraper and ink pump are dirty or not.

07

There will be air inside the newly installed nozzle, so it will not print properly immediately, only after the air of the nozzle is completely exhausted out, will color registration be fine. Specific steps as below:

First of all, intermittent cleaning is workable (only 2 times cleaning every time, and then cleaning 2 times one more time after 30 minutes.

If cleaning many times in continuous, it will make the cleaning pump storage ink, this will not only make mixed printing color, ink leakage

but also waste ink.

Secondary, it is better to print some pictures, lets the nozzle discharge the air during the work.

Last, if the machine has already led out the waste ink tube, power off in advance, and then use one syringe with a rubber tube to draw out the waste ink until extract 3-5 ml, and then turn on the machine, cleaning one more time by machine in normal. This is equivalent to artificially extract out the inside air. The defect is easy to make cleaning pump pile-up of inks.